PRODUCT FEATURES

Double Gear Pump Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who is Uphyd.com

Uphyd.com have seen that today there are also many hydraulic power pack companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uphyd.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

The Ultimate Guide to the Hydraulic Gear Pump

When it comes to hydraulic gear pumps, there is a lot of information out there. It can be hard to figure out what you need, and even harder to find the right pump for your specific needs.

In this article, we will break down everything you need to know about hydraulic gear pumps so that you can make an informed decision when purchasing one. We’ll discuss the different types of hydraulic gear pumps available and what each one is best suited for, as well as tips on how to choose the right pump for your business.

So whether you’re a wholesaler looking for information on which pump to stock, or a small business owner who needs a new hydraulic gear pump, read on for everything you need to know!

Table of contents

1. What Is a Hydraulic Gear Pump?

A hydraulic gear pump is a type of positive displacement pump that is used to move hydraulic fluid. The hydraulic fluid is typically moved by gears, which are enclosed in a housing. The hydraulic gear pump is a popular choice for many industries because it is able to move large amounts of fluid at high pressures.

2. How Does the Hydraulic Gear Pump Work?

The hydraulic gear pump works by using gears to move hydraulic fluid through a housing. The gears are meshed together, and as they turn, they draw hydraulic fluid into the pump. The hydraulic fluid is then forced through the housing and out of the pump.

3. The Components and Their Function

The hydraulic gear pump has different parts that work together to make it function. Here are the different parts and their function:

Prime Mover

The small hydraulic gear pump is powered by a prime mover, which can be an electric motor, internal combustion engine, or another source of power.

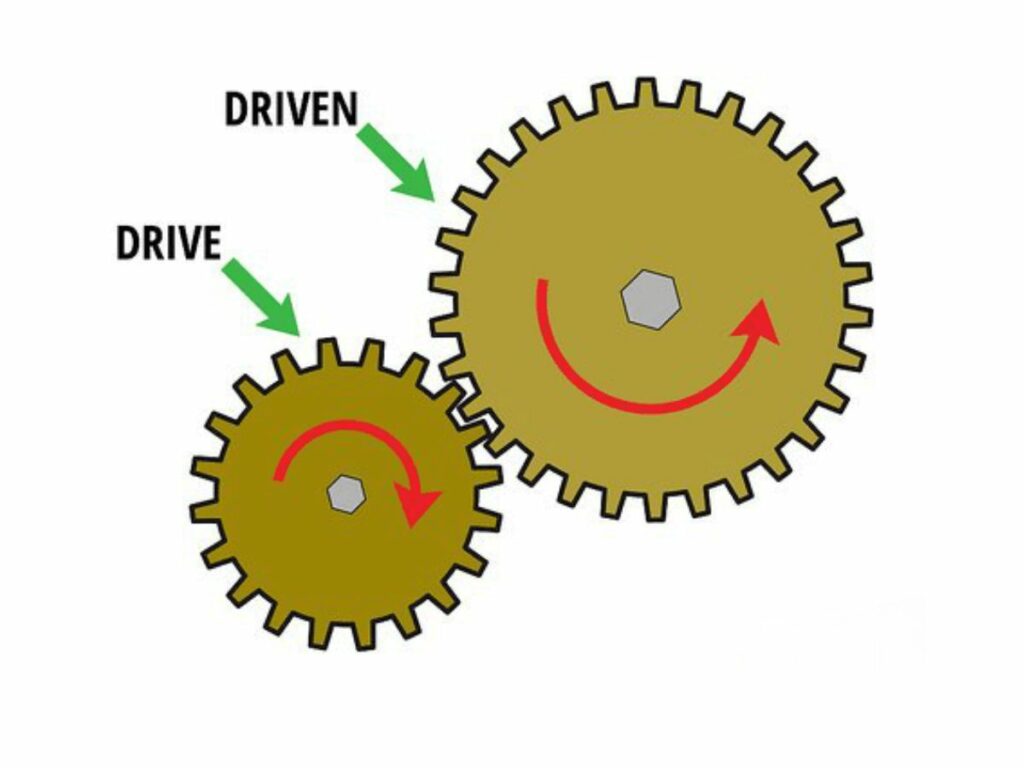

Driver Gear

The driver gear is connected to the prime mover and turns the other gears in the pump. This gear is also known as the driving gear, input shaft gear, or pump drive gear.

Driven Gear

The hydraulic gear pump has gears that are meshed together. The driven gear is turned by the driver gear and in turn, it turns the other gears in the pump. This gear is also known as the output shaft gear, driven shaft gear, or idler gear.

Housing

The housing contains the gears and other parts of the hydraulic tipper pumps. It also provides a place for hydraulic fluid to be pumped.

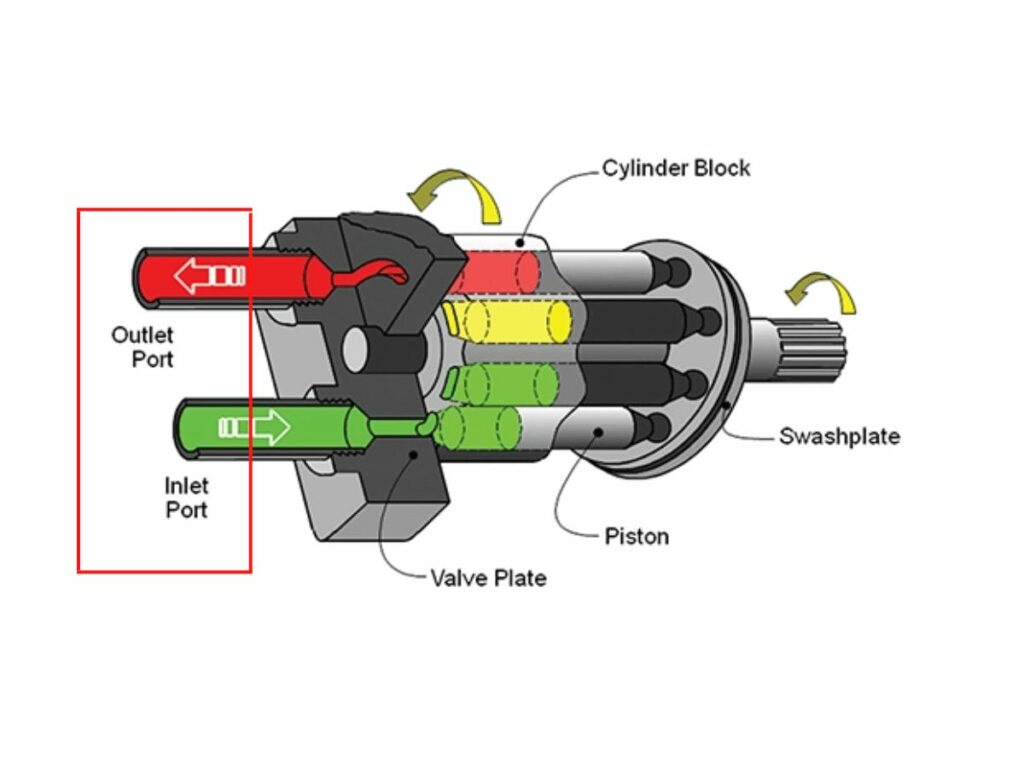

Inlet Port Or Suction Side

The inlet port is where hydraulic fluid enters the hydraulic gear pump. This allows the hydraulic fluid to be drawn into the pump so it can be pumped to the outlet side.

Outlet Port Or Discharge Side

The outlet port is where hydraulic fluid is discharged from the hydraulic aluminum gear pump. This allows the hydraulic fluid to be pumped out of the pump and into the hydraulic system.

Pressure Relief Valve Or Safety Valve

The hydraulic triple gear pump has a pressure relief valve or safety valve to help protect the pump from excessive pressure. This valve opens when the hydraulic fluid pressure gets too high and allows the hydraulic fluid to bypass the pump.

Seals

The hydraulic gear pump has seals to help keep the hydraulic fluid from leaking out of the pump. These seals are located between the gears and between the housing and the shafts.

These are the different parts of the hydraulic gear pump and their function. Now that you know the different parts, you will be able to understand how the hydraulic commercial gear pump works.

4. 2 Key Principle of Gear Pump

When it comes to hydraulic gear pumps for sale, there are 2 key principles that are important to understand in order to properly operate and maintain your equipment. These 2 key principles are what make hydro gear pump so efficient and effective.

#1 They Rely On Gears To Move Fluid

Gear pumps rely on gears to move fluid. The gears rotate in opposite directions, trapping fluid in between them and forcing it to move through the pump. This is an efficient way to move fluid and can generate high hydraulic pressures.

#2 Self Priming

Gear pumps are self-priming. This means that they can start pumping fluid even if there is no fluid in the pump, to begin with. This is because the gears create a vacuum as they rotate, which sucks fluid into the pump.

Keep these principles in mind when using or troubleshooting gear driven hydraulic pumps! These will be important later on.

5. 4 Types of Hydraulic Gear Pumps

There are 4 main types of hydraulic gear pumps. Let’s take a closer look at each one.

| Type | Description |

|---|---|

| #1 External Gear Pumps | External gear pump with motors is the most common type of hydraulic gear pump. They consist of 2 gears that mesh together, with one gear rotating inside the other. As the gears rotate, they create a vacuum that sucks fluid into the pump from the inlet port. The fluid then gets trapped between the gears and is carried around to the outlet port, where it is ejected from the pump. |

| #2 Internal Gear Pumps | This is similar to external gear pumps, except that the gears are reversed. In an internal gear pump, the smaller gear (the “pinion”) is inside the larger gear (the “ring gear”). As the gears rotate, they again create a vacuum that sucks fluid into the pump. However, in this type of pump, the fluid is carried around to the outlet port by the teeth on the inner surface of the ring gear. |

| #3 Gerotor Pumps | Gerotor pumps are a type of internal gear pump. They consist of an inner and outer rotor that mesh together. As the rotors rotate, they trap fluid between them and carry it around to the outlet port. |

| #4 Vane Pumps | Vane pumps are a type of positive displacement pump. They consist of a rotating shaft with vanes that slide in and out as the shaft turns. As the vanes slide out, they create a cavity that sucks fluid into the pump. The fluid is then trapped between the vanes and carried around to the outlet port. |

These are the 4 main types of hydraulic gear pumps. Now that you know a little bit about each one, you can decide which type is best for your needs.

6. 5 Industry Application

A hydraulic gear pump is a powerful device that has many industrial applications. Some of the most common applications are:

#1 Mining

A high-pressure hydraulic gear pump is essential for mining operations. It is used to move large quantities of earth and ore, as well as to power hydraulic equipment.

#2 Construction

A hydraulic gear pump is used in construction to power heavy equipment like bulldozers and cranes. It can also be used to move concrete and other building materials.

#3 Forestry

A hydraulic gear pump is used in forestry to move logs and lumber. It can also be used to power heavy equipment like grapple trucks and wood chippers.

#4 Agriculture

A hydraulic gear pump is used in agriculture to power farm machinery like tractors and harvesters. It can also be used to move fertilizer and other agricultural products.

#5 Manufacturing

A hydraulic gear pump is used in manufacturing to power factory machines like presses and mills. It can also be used to move materials and products within a factory setting.

These are just a few of the many industries that rely on tandem hydraulic gear pumps. If you need a reliable and powerful hydraulic pump, consider a hydraulic gear pump.

7. The Average Cost of Hydraulic Gear Pump

The average cost of a hydraulic gear pump ranges from $1,000 to $10,000, depending on the size and features of the pump. The hydraulic gear pump is an important piece of equipment for many industrial and commercial applications. Because of its importance, the hydraulic gear pump can be a costly investment.

Before purchasing a hydraulic gear pump, it’s important to consider the needs of your application and select the right model for it. Doing so can help you avoid costly repairs and replacements in the future.

8. How to Work With Hydraulic Gear Pump Manufacturer

If you’re looking to work with a hydraulic gear pump manufacturer, there are a few things you need to keep in mind. Here are some tips on how to work with hydraulic gear pump manufacturers:

Make Sure You Have A Clear Understanding Of Your Needs

Before you start working with a hydraulic gear pump manufacturer, you need to have a clear understanding of your needs. What are you looking for in a gear pump? What kind of applications will it be used for? Once you have a good understanding of your needs, you can start looking for manufacturers that can meet them.

Communicate Your Needs Clearly To The Manufacturer

Once you’ve found a manufacturer that you think can meet your needs, it’s important to communicate your needs clearly to them. Make sure they understand what you’re looking for and what your requirements are. This will help them provide you with the best possible product.

Be Willing To Negotiate

When you’re working with a motor gear pump manufacturer, you need to be willing to negotiate. There may be some aspects of the product that you’re not entirely happy with, but if you’re willing to compromise, you may be able to get a better deal.

Get Everything In Writing

Whenever you’re working with a hydraulic gear pump manufacturer, it’s important to get everything in writing. This includes the price of the product, the delivery date, and any other important details. This will help you avoid any misunderstandings down the road.

Be Prepared To Walk Away

If you’re not happy with the terms of the deal, or if you don’t feel like the manufacturer is meeting your needs, don’t be afraid to walk away. There are plenty of other hydraulic gear pump manufacturers out there, and you’re sure to find one that’s a better fit for you.

Following these tips will help you have a successful experience when working with a hydraulic gear pump manufacturer. With these tips, you’re sure to find the perfect hydraulic gear pump manufacturer for your needs.

9. Where to Source for a Reliable Manufacturer

When sourcing for a hydraulic gear pump manufacturer, it is important to find one that is reliable and has a good reputation in the market. There are many places where you can find such manufacturers, here are some of them:

Online Directories

There are online directories that list manufacturers of hydraulic gear pumps. This is a good place to start your search as you can easily compare different manufacturers and find one that suits your needs.

Trade Shows

Attending trade shows is another great way to find reliable manufacturers of hydraulic gear pumps. This is because you will get to meet the manufacturers in person and get to know more about their products.

Industry Associations

There are industry associations that represent manufacturers of 2 stage gear pumps. This is a good place to find reliable manufacturers as they will be vetted by the association.

Social Media

Social media is a great place to find manufacturers of hydraulic gear pumps. This is because you can easily find reviews of different manufacturers and get an idea of which ones are reliable.

These are some of the places where you can find reliable manufacturers of hydraulic gear pumps. Do your research and find one that suits your needs. Alternatively, you can also buy from us at Uphyd. We offer a wide range of hydraulic gear pumps that are made from high-quality materials. Visit our website today to learn more about our products.

10. 4 Buying Tips About Hydraulic Gear Pump

When shopping for a hydraulic gear pump, there are four main things you should keep in mind:

#1 Flow Rate

The flow rate of a hydraulic gear pump is the amount of fluid that the pump can move per revolution. To calculate the flow rate, simply multiply the pump’s displacement by the speed of the input shaft.

#2 Pressure

The pressure of a hydraulic gear pump is a measure of how much force the pump can generate. To calculate the pressure, simply multiply the flow rate by the pump’s efficiency.

#3 Pump Mounting

There are 2 main types of pump mounts – SAE and NPT. SAE pumps are generally used for low-pressure applications, while NPT pumps are designed for high-pressure applications.

#4 Shaft Rotation

The direction of shaft rotation is important to consider when selecting a hydraulic gear pump. Some pumps are designed for clockwise rotation, while others are designed for counterclockwise rotation. Be sure to select a pump that is compatible with the direction of shaft rotation on your application.

By keeping these 4 factors in mind, you will be able to select the best hydraulic gear pump for your specific application.

11. Conclusion

So there you have it, the ultimate guide to hydraulic gear pumps. This comprehensive guide should give you a good idea of what to look for when purchasing a hydraulic gear pump.

If you still have any questions or would like more information on specific parts of the hydraulic gear pump, don’t hesitate to contact us at Uphyd. We’re always happy to help our customers find the best products for their needs.

FEATURE BLOGS

READY TO LEARN MORE?

Find everything you need to know about hydraulic pumps in this comprehensive guide.